Main Reasons to Choose the Modular Bathroom Method

Cost efficiency

- Construction of repetitive structures in a factory environment protected from weather conditions.

- Year-round assembly due to the absence of wet processes.

Labor savings

- No need to coordinate trades on-site.

Construction and installation speed

- Compared to wet masonry processes, construction time is reduced by up to 75%.

- On-site installation takes only a fraction of a work shift.

Reliability

- A detailed design process identifies and resolves technical issues before construction begins.

- Material compositions are verified and certified by technical and testing institutes.

- Controlled quality of execution prevents the occurrence of defects.

Environmental sustainability

- Waste minimization through the modularity of materials used.

- Reducing CO2 footprint with "Environmental Product Declarations" (EPD) issued for materials.

Environmental sustainability

- Waste minimization through the modularity of materials used.

- Reducing CO2 footprint with "Environmental Product Declarations" (EPD) issued for materials.

Construction Process of Bathroom Modules

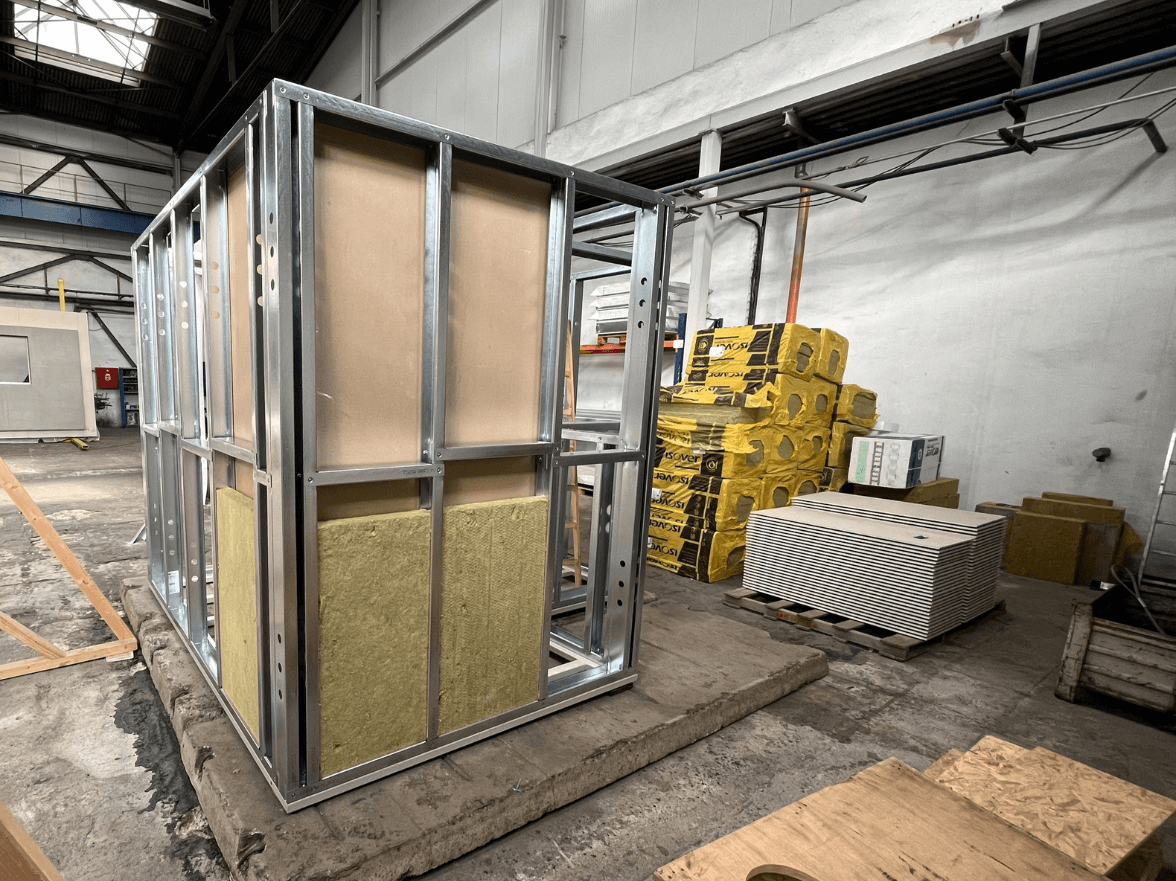

Based on the technical documentation, the groundwork is prepared for the production of steel profiles, which later form the basic structure of walls, floors, and ceilings. The connection of the walls, floor, and ceiling creates the fundamental structure of the room. All joints are thoroughly sealed to ensure the strength of the entire framework. For modules with a concrete floor, the floor is produced by casting concrete into molds.

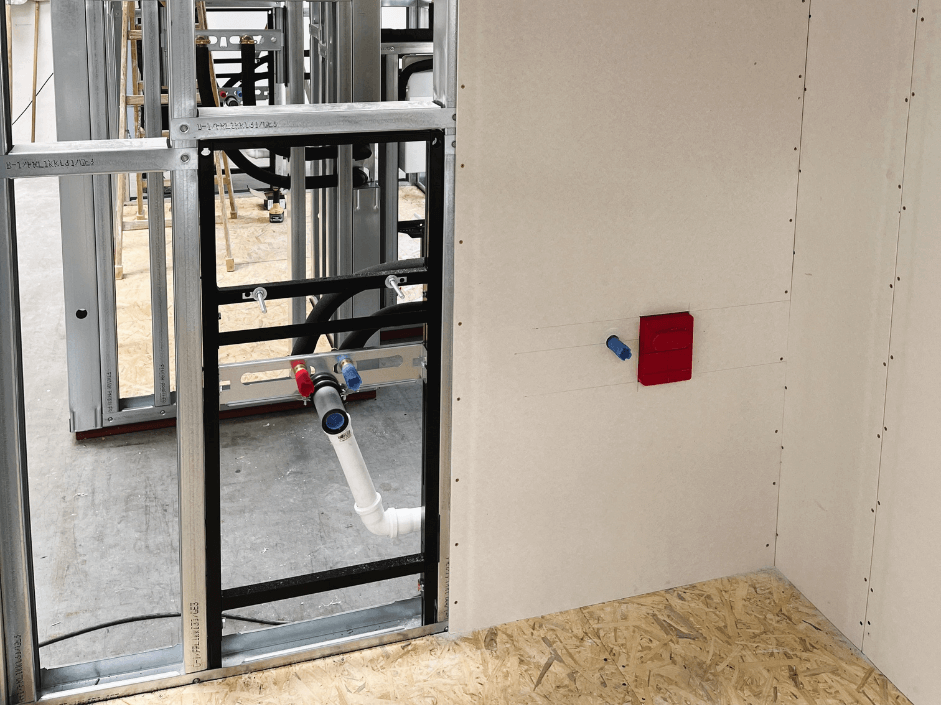

On the interior side of the walls, RigiStabil construction drywall boards are installed, characterized by high flexural strength and surface hardness. Additionally, the boards are impregnated and fire-resistant. The wall structure is complemented with suitable acoustic mineral insulation, such as Isover AKU or polyurethane foam, to achieve the required sound insulation. All walls are treated with waterproofing.

According to the project documentation and in compliance with regulations, water, electricity, and waste piping are installed.

According to the investor's requirements and the architectural design, wall and floor cladding, installation of sanitary equipment, and other fixtures are carried out. All using certified materials, such as suitable flexible adhesives and reliable grouting compounds. Finally, a pressure test is conducted to verify the tightness of the entire system and all installations.

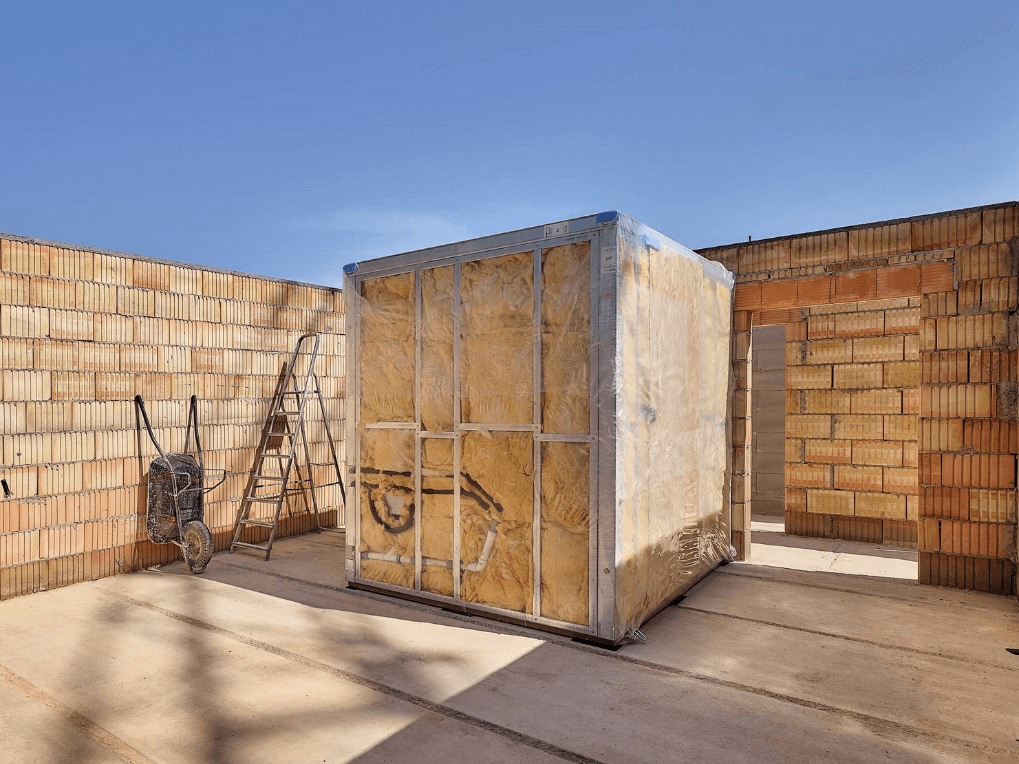

The finished modules are sealed and protected with a welded foil against moisture. They are then ready for transport and subsequent installation in the building, where they are connected to the prepared utilities.

Bathroom module parameters

● Airborne sound insulation at a level of 55 dB.

● Impact sound insulation of 45 dB (compliant with EU standards).

● Construction weight of 500–750 kg.