Why choose ENVEO panels

USABLE SPACE

- Narrower walls lead to higher usable room area

- the wall of the perimeter panel is 3x thinner than that made of brick blocks

REDUCTION OF WEIGHT

- low panel weight

(95-115 kg/m2) - minimization of waste

– construction generates a maximum of 1% waste due to the simplicity of the system.

WORLDWIDE TECHNOLOGY

- the technology of inserted or prefabricated lightweight panels is well-known

and proven through years of practice - it has been used for many years

in countries like the United Kingdom, the Netherlands, South Africa and others

ENVIRONMENTAL PROTECTION

- modularity ensures maximum utilization of building materials

- EPD are provided for the materials used

- reduced transportation = lower CO2 emissions

CONSTRUCTION SPEED

- panels are manufactured

off-site - prefabrication shortens construction time by 75% compared to traditional

wet masonry processes - the building envelope is installed

in a very short time - on-site time is significantly reduced

FLEXIBILITY

- variability in facade surface finishes

- technology suitable for both new constructions and building renovations, for residential

as well as non-residential projects

LABOR SAVINGS

- on-site assembly carried out by

4 trained personnel - year-round installation possible due to the absence of wet processes

- reduced time required for scaffolding occupancy

RELIABILITY

- technical testing conducted as prescribed by standards

- a detailed design process identifies and resolves issues

before construction begins - controlled manufacturing process

- certification

Innovative and Proven Solution!

ENVEO panels are manufactured off-site. They create a secondary structure, fixed to the floor and ceiling within the primary frame. They serve as a lightweight infill for the perimeter construction. Installation is carried out from inside the building.

The panel is placed at the edge of the slab or pre-hung on the facade, allowing continuous installation of insulation and external finishes outside the main frame. This is usually the most cost-effective solution, especially for facade renovations.

The system uses Saint-Gobain products

- Isover Aku - acoustic insulation

- Isover Vario® KM Duplex UV - vapour-permeable membrane

- RigiStabil – board with high flexural strength

and surface hardness - Glasroc X – board with increased water resistance and mould resistance due to the absence of organic components

- weber therm - Insulation system

ENVEO Construction Detail Solutions

The construction details are designed in accordance with the static, mechanical, acoustic, and thermal requirements of ČSN (EN) standards.

● Thermal assessment of details: Verification of critical points regarding condensation (10 details).

● Static assessment: Verification of anchor design and panel connections.

● Acoustic assessment: Verification of material compositions through acoustic testing.

● Fire assessment: Verification of material compositions through fire testing according to ČSN (EN) standards.

Verified thermal parameters serve as a general technical solution. For a specific project, local climatic conditions, building dimensions, static assessment, fire safety, and specifics based on the location of the particular building must be considered.

ENVEO Adapts to Every Project

The building is designed as airtight and insulated. The details are engineered to prevent thermal bridging while achieving the best possible acoustic performance in terms of airborne sound insulation throughout the building.

The overall thickness of the layers and the selection of appropriate materials achieve:

● Passive standard – this indicates significantly low overall energy demand for heating and ventilation. It is proven by the thermal conductivity coefficient (U-value) of the perimeter structures [W/m²K]

● Comfortable acoustics – due to high airborne sound insulation of individual structures [dB]

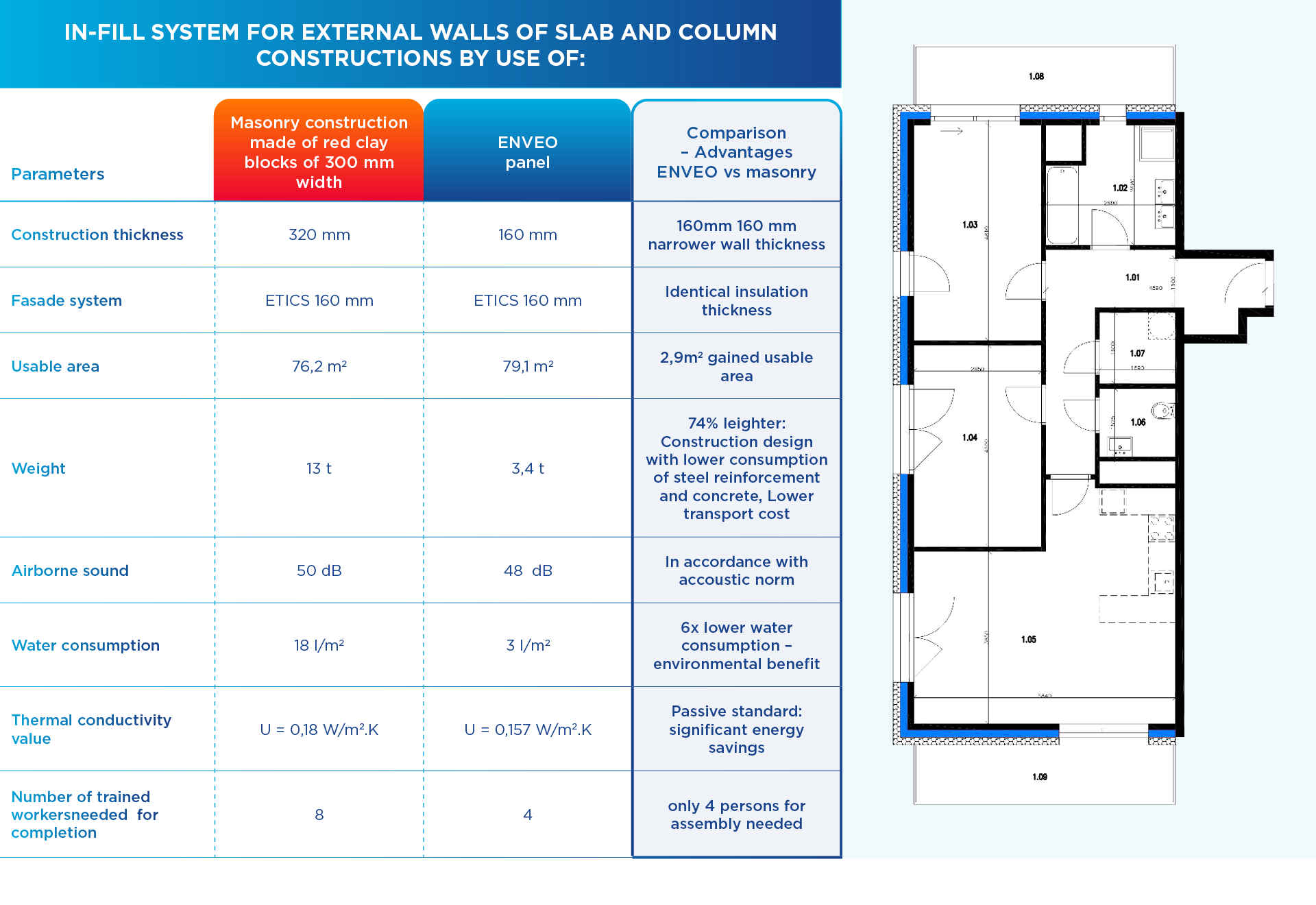

3+1 Apartment Solution with ENVEO Panels Compared to Masonry

Compare selected parameters of the ENVEO system with commonly used masonry materials

in terms of acoustics, weight, water consumption, usable space, and thermal resistance.

References

The Lighthouse - Isle of Dogs, Docklands, London

Mast Quay, Woolwich - London

Colehill Development - Leith, Edinburgh

Certification

● Construction Technical Certificate is a document that confirms the compliance of a construction project with the requirements set by applicable legal regulations and the building permit

● EPD Environmental Declaration about product is a set of measurable information about the environmental impact of a product throughout its entire lifecycle

● ENVEO Front Technical Data Sheet - product information and specifications

Prefabrication is the way to simplify and accelerate construction.

Modular bathrooms

Floor panels

Acoustic absorbers

Contact us

We tailor panels to fit every project.